YODEE yug nyob rau hauv Guangzhou, uas muaj lub npe ntawm lub ntiaj teb no ua Hoobkas nyob rau hauv 2012. Los ntawm kev tsim, tsim thiab kev muag khoom tau sau nyob rau hauv kaum xyoo dhau los, peb muaj ib tug ua tiav Hoobkas, ib tug zoo heev pab neeg thiab ntau yam tseem ceeb heev domestic thiab txawv teb chaws koom tes.

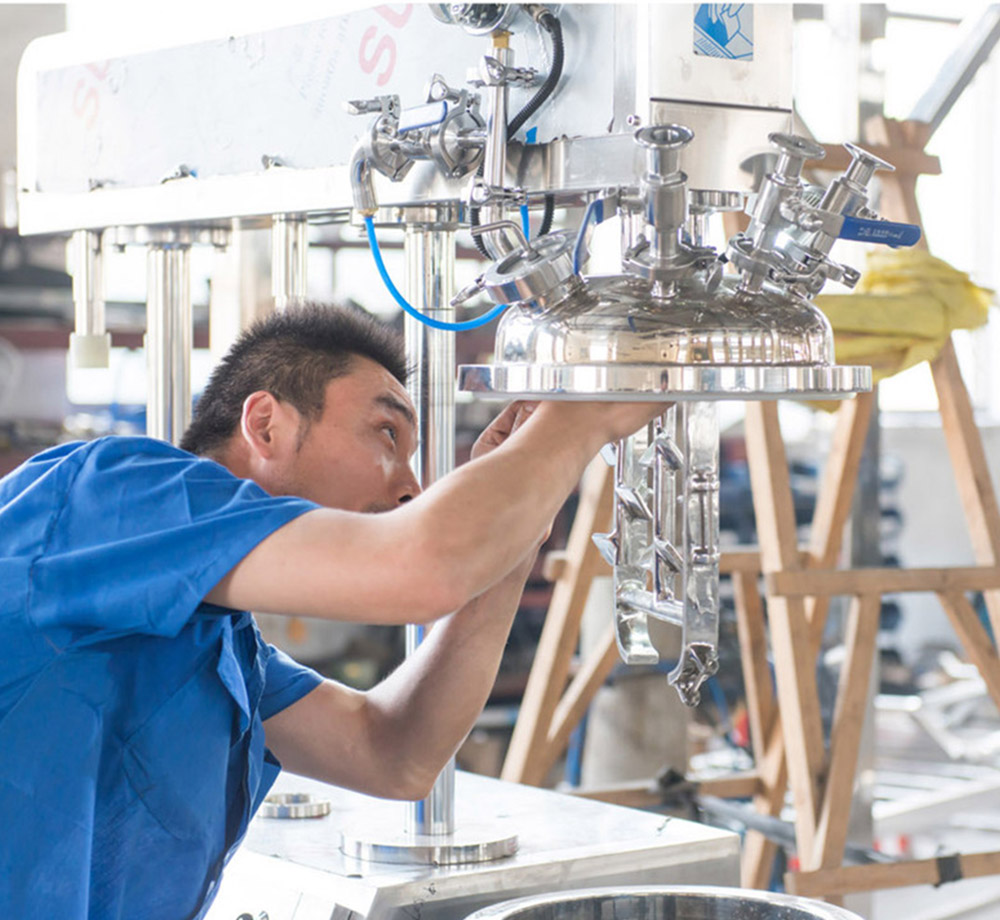

YODEE ua tib zoo saib xyuas qhov zoo ntawm lub tshuab thiab cov neeg siv kev paub.Nyob rau hauv tus txheej txheem ntawm kev nrhiav kom tau zoo, peb niaj hnub innovate peb technology thiab nruj me ntsis tswj qhov zoo ntawm txhua yam nyob rau hauv xaiv cov ntaub ntawv.Ua ntej txhua lub tshuab xa mus rau cov neeg siv khoom, peb yuav tsum tau rov qab xyuas thiab sim ntau yam kev ua tau zoo los xyuas kom meej tias lub tshuab yog nyob rau theem siab tshaj plaws.

Kev xaiv ntawm stainless hlau raw khoom:

| Qauv | Tsis yog ion (%) | Corrosion kuj | Scope ntawm daim ntawv thov |

| SUS 201 | 3.5-5.5% | qis | Kho kom zoo nkauj teb, Tsev |

| SUS 301 | 6% -8% | qis | Auto qhov chaw, Dviation |

| SUS 304 | 8% -10.5% | Nruab nrab | Kev lag luam, Food Field |

| SUS 316 | 10% -14% | Siab | Tshuaj pleev ib ce, Khoom noj khoom haus, Pharmaceutical teb |

| SUS 316L | 12% -15% | Siab heev | Tshuaj pleev ib ce, Khoom noj khoom haus, Pharmaceutical teb |

Tom qab ua tiav cov kev xaiv ntawm cov ntaub ntawv, YODEE yuav txiav raws li cov duab kos ntawm cov cav tov xav tau los ntawm txhua tus neeg siv khoom thiab raws li cov lus qhia thiab qhov ntau thiab tsawg, peb sim siv cov ntaub ntawv puv-nplooj stainless hlau es tsis txhob siv cov khoom siv stainless hlau spliced.

Cov ntaub ntawv stainless hlau txiav yog welded thiab polished raws li tus txheej txheem, thiab YODEE tseem muaj kev sib txawv rau vuam tshuab thiab polishing yuav tsum tau.Lub tshuab tsim khoom yog tsim los ntawm kev sib tsoo vuam, thiab cov raj xa dej feem ntau yog ob sab welding.Polishing yog 300 mush daim iav polishing.

Nyob rau hauv lub tshav pob ntawm machining, muaj cov nram qab no welding technologies:

1. Spot welding technology: Nws tuaj yeem txuas tau sai sai ntawm ob qhov stainless hlau, tab sis qhov tsis zoo yog tias nws tsis muaj zog txaus, thiab muaj ntau qhov sib txawv ntawm lawv, thiab muaj cov perforations thiab vuam slag.Tsawg kev xav tau rau cov welders.Cov aesthetics kuj tsawg.

2. Zawg Welding Technology: Lub Vuam Qhov Chaw yog qhov tseem ceeb, sib kis tau zoo dua, muaj qee qhov chaw zoo nkauj, thiab lub loog yog qhov nruab nrab.

3. Shaking welding tshuab: vuam qhov chaw ntawm ib leeg tuaj yeem ua tau zoo sib xws, txhim khu kev qha, tsis muaj qhov sib txawv, tsis muaj perforation, tsis muaj vuam slag, thiab siab zoo nkauj.

4. Ob chav-sided gas-filled welding tshuab: siv cov pa roj carbon dioxide los tiv thaiv qhov vuam nto, nrog lub pas dej me me, qhov vuam zoo dua, zoo nkauj zoo nkauj, tsis muaj vuam slag, tsis muaj kev soj ntsuam, thiab vuam zoo.

Txheej txheem polishing:

1. Preliminarily ntxhib sib tsoo thiab polishing cov khoom, thiab siv xuab zeb abrasive zom cov workpiece nrog ntxhib nto kom tshem tawm cov macro tsis sib xws.

2. Tom ntej no, ntxiv polish rau lub hauv paus ntawm kev sib tsoo ntxhib kom tshem tawm cov khoom sib tsoo.Tom qab cov txheej txheem no, qhov chaw ntawm lub workpiece yog maj mam du thiab ci.

3. Thaum kawg, ua tiav cov kauj ruam tom ntej ntawm kev sib tsoo zoo thiab polishing, kom lub workpiece tuaj yeem ua tiav qhov zoo tshaj plaws ci ci thiab zoo nkauj.

YODEE tus khub sib sau ua ke tag nrho cov khoom, thiab ua ntej kev hloov kho thiab tshuaj xyuas.

Tag nrho YODEE workpieces tau sib sau ua ib lub tshuab ua tiav, thiab tus kws kuaj xyuas zoo ua 24-teev ua ntej xa khoom ntawm lub tshuab hauv lub hoobkas.